Primary & Secondary Robotic Packaging Equipment

From individual pick and place items to prepackaged products and clamshells, Apex has the proven experience to

help you with everyday packaging challenges in the food, bakery, pharma and dairy industries.

Primary Packaging

Collaborative and industrial robotic solutions

to handle "raw" unpackaged products — from

soft grip to tiny individual items.

Secondary Packaging

Collaborative and industrial robotic solutions

to handle packaged items that are generally transferred into a box or container.

Packaging Capabilities

Soft grip, primary, secondary, pick n place, randomized, sensitive and ultra light to heavy payloads.

Direct from conveyor and trays to boxes, cartons and containers.

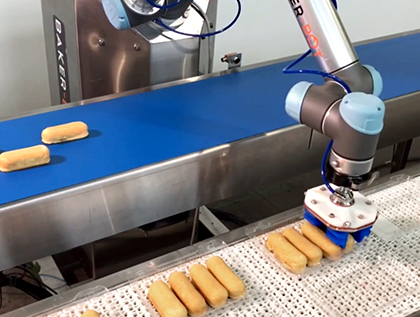

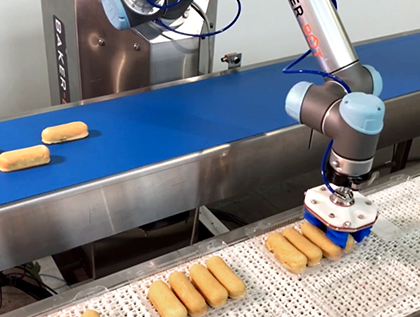

Primary Packaging

Also known as Pick 'n' Place, Primary Packaging refers to handling ingredients before they have been packaged. Most commonly,

post bake or items that have been prepared and ready for "retail"

packaging.

Common items for Primary Packaging are bread, mini chocolates, muffins, buns, cookies, snack cakes and meat products such as pepperoni sticks, beef jerky and frozen chicken breasts.

Various end effectors (end of arm attachments) are available such as soft grip or multi-nozzle heads.

Secondary Packaging

Secondary Packaging generally refers to items that have been packaged and require placement into containers for shipping

such as cardboard boxes.

Common items for Secondary Packaging are bread or buns in bags, clamshells with muffins, buns, cookies and cupcakes, pie or pizza in

a box, and individual items such as jugs of protein powder, vitamins in small containers or energy drink packages.

Various end effectors (end of arm attachments) are available such as soft grip or multi-nozzle heads.

Benefits of Working with Apex Motion Control

Apex Motion Control has 25 years of experience helping wholesale industrial bakeries streamline production,

increase throughput, consistency and accuracy while helping them build a plan for future business growth.

Benefits of Apex Motion Control Equipment

Versatile modular solutions . Reduce repetitive strain to workers . Increase productivity and consistency

Standard and custom configurations . Remote & Onsite Support & Service . Integrates easily with other OEM's

Reach out and let us know what your Packaging Needs Are.